A simple yet potent tool, paracord’s reputation in the outdoor gear realm is unparalleled. But how strong is it really? Dive in as we unravel the strength and versatility of the various paracord types.

Paracord’s Origins and Evolution

1. Birth in Battle:

The story of this versatile cord begins on the battlefields of World War II. Initially designed as suspension lines for parachutes, it quickly became a favorite among soldiers. Its strength, flexibility, and lightweight nature made it an indispensable tool in the heat of combat. Soldiers discovered a myriad of uses for it, from securing equipment to emergency repairs. This wartime necessity laid the foundation for its widespread popularity in the years to come.

2. Transition to Civilian Life:

Post-war, the surplus of this material found its way into the hands of civilians. Its reputation for durability and adaptability quickly spread, leading to its integration into everyday life.

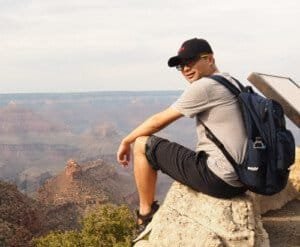

- Outdoor Enthusiasts: Hikers, campers, and climbers embraced it for its multifunctional uses in the great outdoors.

- Crafting Community: The crafting world saw potential in its flexibility, leading to the creation of bracelets, belts, and other wearable items.

- Survivalists: Recognizing its potential in emergency situations, survivalists adopted it as a staple in their kits.

- Fashion Industry: Beyond its practical uses, it began to make waves in the fashion world, with designers incorporating it into their creations.

- Innovation and Adaptation: Over the years, various types and colors emerged, catering to specific needs and preferences, further solidifying its place in modern culture.

3. Modern-Day Applications:

Today, its uses span a vast spectrum. From emergency services using it in rescue missions to schools teaching children basic knotting techniques, its influence is undeniable. Its resilience and versatility have made it a favorite in various industries, from construction to maritime, showcasing its adaptability and enduring appeal. For a deeper dive into its modern applications, check out this comprehensive guide.

4. Future Prospects:

Peering into the horizon, the versatility of this cord knows no bounds. As we delve deeper into material advancements and recognize its myriad uses, its journey is just beginning. Scientists are on the quest to enhance its longevity, sustainability, and task-specific attributes. As we stride forward with technology, the enduring tale of this exceptional cord unfolds, heralding a future as diverse and profound as its history.

Breaking Down Paracord’s Strength

1. Historical Context

The legacy of this cord’s strength can be traced back to World War II, where it was initially used as parachute suspension lines. Its ability to bear the weight of soldiers and equipment without snapping was a testament to its unparalleled strength. This military-grade durability set the stage for its widespread adoption in various applications, both in combat scenarios and civilian life.

2. Material Composition

The secret to its impressive strength lies in its unique construction. Comprising multiple inner strands encased in a woven outer sheath, this design ensures both durability and flexibility.

- Inner Strands: These provide the core strength, bearing weight and tension.

- Outer Sheath: Offers protection to the inner strands and adds to the overall tensile strength.

- Nylon Construction: The choice of nylon as the primary material contributes to its elasticity and durability.

- Interwoven Design: The manner in which the strands are woven plays a crucial role in distributing weight and tension evenly.

- Resistance to Elements: Its ability to withstand environmental factors like UV rays and moisture further enhances its strength.

- Adaptability: Despite its strength, it remains flexible, allowing for various applications without compromising its integrity.

3. Tensile Strength Variations

Not all cords are created equal. Different types come with varying tensile strengths, suited for specific tasks. The most renowned variant boasts a strength of 550 pounds, but there are both lighter and heavier-duty versions available, catering to diverse needs.

4. Practical Implications

Understanding its strength is pivotal in various scenarios. For outdoor enthusiasts, it offers reliability in tasks like setting up shelters or rappelling. In survival situations, its strength can be the difference between life and death. Moreover, in crafting, knowing its weight limits ensures the creation of durable and long-lasting products.

- Safety Protocols: Ensuring that it’s used within its weight limits prevents accidents.

- Versatility in Use: From securing heavy loads to intricate crafting, its strength offers a wide range of applications.

- Durability Over Time: With proper care, it retains its strength, resisting wear and tear.

- Economic Implications: Due to its durability, it offers long-term savings by reducing the need for replacements.

- Eco-Friendly Aspect: Its long lifespan means less waste, contributing to sustainability.

- Innovation and Research: Continuous research aims to further enhance its strength, opening doors to even more applications.

5. Challenges and Limitations

While its strength is commendable, it’s essential to recognize its limitations. No material is invincible. Overloading, prolonged exposure to harsh conditions, or using it beyond its intended purpose can compromise its integrity. Being aware of these challenges ensures safe and optimal use. For a detailed understanding of its limitations and best practices for care, refer to this comprehensive guide.

Navigating the Types of Paracord by Their Strength

1. Introduction to Tensile Strength

Tensile strength refers to the maximum amount of weight a material can support without breaking. In the world of cords, this strength varies significantly based on its type and construction, making it essential to choose the right kind for specific tasks.

2. The Renowned 550 Variant

Often dubbed the “universal cord,” the 550 variant is known for its impressive 550-pound tensile strength. This makes it a favorite for a wide range of applications, from outdoor adventures to crafting projects.

- Composition: Typically consists of seven to nine inner strands, providing its robust strength.

- Popular Uses: Ideal for heavy-duty tasks like securing equipment or building shelters.

- Availability: Widely available due to its popularity and versatility.

- Limitations: While strong, it’s essential to avoid overloading to ensure longevity and safety.

3. Lighter-Duty Cords – Type I & II

These are the more delicate siblings in the cord family. With a lower tensile strength, they’re perfect for tasks that require finesse rather than brute strength, such as intricate crafting or lightweight securing.

4. Heavy-Duty Variants

For tasks that demand even more strength than the 550 can offer, there are heavier-duty options available. These cords are designed to bear substantial weight, making them ideal for industrial applications or extreme outdoor scenarios.

- Material Enhancements: Often reinforced with additional strands or specialized materials for added strength.

- Specific Uses: Commonly used in construction, maritime activities, or rescue operations.

- Safety Protocols: Given their strength, it’s crucial to follow safety guidelines to prevent accidents.

- Cost Implications: Typically pricier due to their enhanced features and strength.

5. Specialty Cords

Beyond the standard strength classifications, there are specialty cords designed for unique purposes. These might include reflective cords for visibility, elastic variants for stretch, or even fire-resistant types for specific safety scenarios. For a comprehensive overview of these specialty variants and their unique applications, explore this detailed guide on specialty paracord types.

6. Environmental Factors Affecting Strength

External factors, such as UV rays, moisture, or extreme temperatures, can impact a cord’s strength. It’s essential to consider these elements when choosing a type, ensuring it’s suited for the intended environment.

7. Making an Informed Choice

Understanding the various strength levels is just the beginning. It’s crucial to assess the specific needs of a task, consider external factors, and then make an informed choice. This ensures not only the success of a project but also safety and durability.

Factors That Influence Paracord Strength

1. The Essence of Its Might:

Dive deep into the heart of this cord, and you’ll find a harmonious blend of material and craftsmanship. Nylon, with its resilient character, is often the star of the show. But it’s the artful dance of weaving, the delicate balance of inner strands cradled by a protective outer layer, that truly brings its strength to life. This intricate design ensures an even spread of forces, allowing the cord to bear weight gracefully, without faltering. It’s this union of material and design that crafts the legendary strength we’ve come to rely on.

2. External Environmental Factors

While inherently strong, the cord’s strength can be influenced by external elements.

- UV Exposure: Prolonged exposure to direct sunlight can degrade the material over time, reducing its strength.

- Moisture and Humidity: While it’s resistant to moisture, constant wet conditions can affect its durability. It’s essential to ensure it dries properly to prevent mildew or weakening.

- Temperature Fluctuations: Extreme temperatures, both hot and cold, can impact its elasticity and tensile strength.

- Chemical Exposure: Certain chemicals can have adverse reactions with the cord material, potentially compromising its integrity.

- Abrasion and Wear: Regular friction or rubbing against rough surfaces can lead to fraying, reducing its overall strength and lifespan.

3. Usage and Handling

How the cord is used and handled plays a pivotal role in its strength retention. Constantly subjecting it to loads near its maximum capacity can lead to stretching and reduced tensile strength. Knotting it too tightly or frequently can also weaken specific sections. Moreover, using it for purposes beyond its intended design or not adhering to safety guidelines can compromise its integrity. Proper care, regular inspections for wear and tear, and understanding its limitations are crucial for maintaining its strength and ensuring longevity.

The Real Strength: Stories and Testimonials

1. The Mountain Climber’s Tale

In the treacherous terrains of the Himalayas, a solo climber recounted how the cord became his lifeline. When his ropes failed, it was this trusty cord that he used to rappel down a precarious cliff, proving its unmatched strength.

2. The Survivor’s Gratitude

Stranded in a dense forest after a hiking mishap, a young adventurer shared how she used the cord to build a shelter, create snares, and even fashion a makeshift fishing line, highlighting its versatility in dire situations.

3. The Craftsmen’s Chronicle

Artisans from a small town spoke of the cord’s transformative impact on their craft. From intricate jewelry to woven bags, its durability and flexibility breathed life into their creations, earning rave reviews from customers.

4. The Rescuer’s Reliance

A lifeguard from a popular beach recalled a stormy day when traditional rescue ropes were out of reach. It was the cord that he turned to, pulling multiple swimmers to safety, showcasing its reliability in emergencies.

5. The Traveler’s Testament

An avid backpacker narrated tales from his journeys across continents. Whether securing his tent against desert winds or hanging food away from wildlife, the cord remained his constant companion, emphasizing its global appeal and adaptability.

FAQ

FAQ

Q1: How does the strength of paracord 550 compare to paracord 750?

A: While both are formidable, paracord 750 has a higher tensile strength than paracord 550.

Q2: What distinguishes MIL-C-5040H from other types?

A: MIL-C-5040H is a military specification paracord, designed for rigorous, life-saving applications.

Conclusion

- Recap of the strength levels of the different paracord types.

- Reiteration of the importance of understanding these distinctions for practical applications.

FAQ

FAQ