Permanent matches, a marvel of convenience and sustainability in fire-starting tools, intrigue many with their unique mechanism. This article demystifies how permanent matches function.

A permanent match works by igniting a fuel-soaked wick through friction created when striking a metal rod against a rough surface.

We will delve into the details of their design, mechanism, and components that make permanent matches a reliable fire source.

The Design of a Permanent Match

Overall Structure and Components

A permanent match typically consists of a metal rod (often made of steel), a wick, and a fuel reservoir, all housed within a small, durable casing. The metal rod is designed to strike against a rough surface attached to the casing, generating sparks.

The Metal Rod and Striking Mechanism

The metal rod is the core component of the permanent match. It’s usually coated with a material that produces sparks when struck against the rough surface, typically made of a ferrocerium alloy. This striking mechanism is what ignites the wick soaked in fuel.

Wick and Fuel Reservoir

The wick, often made of cotton or a similar absorbent material, is responsible for drawing the fuel (usually lighter fluid) up from the reservoir to the striking point. The design of the wick and reservoir ensures consistent fuel delivery and efficient burning.

Casing and Durability

The casing of a permanent match is designed for durability and ease of use. Materials like stainless steel or hard plastics are commonly used, providing protection to the internal components and withstanding regular use and environmental factors.

Safety Features and Ergonomic Design

Safety is a crucial aspect of the design. Many permanent matches include features to prevent accidental ignition, such as safety caps or locking mechanisms. Ergonomic considerations, like the grip and ease of striking, are also integral to the design.

The Ignition Mechanism

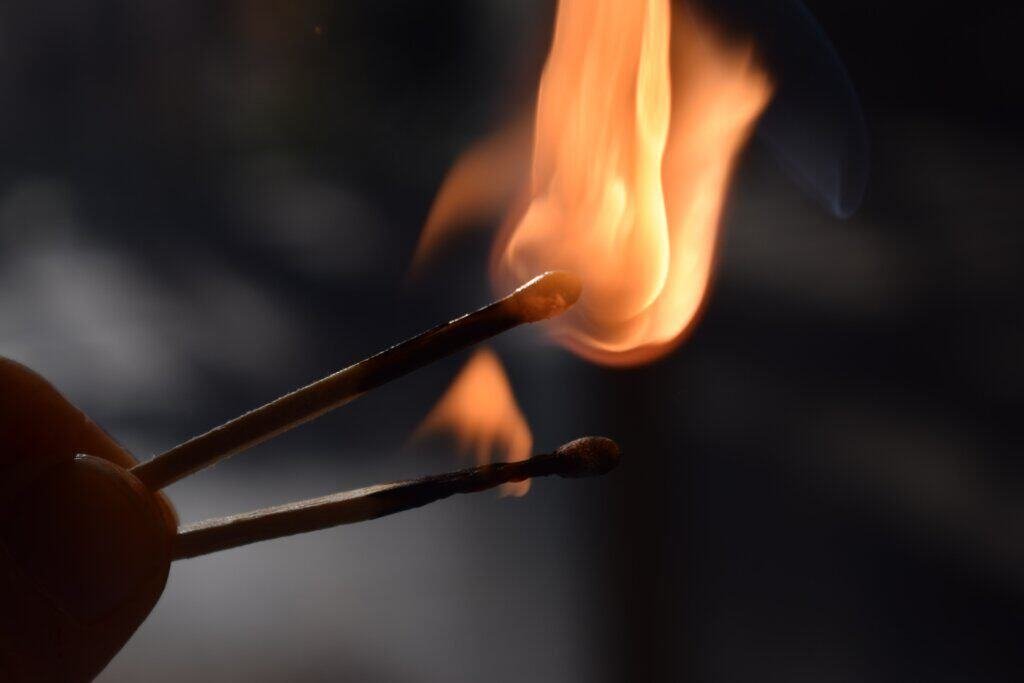

Creation of Sparks through Friction

The ignition process begins when the metal rod, coated with a flammable material, is struck against the rough surface, typically made of ferrocerium. This action creates friction, generating sparks. The heat from these sparks is sufficient to ignite the fuel-soaked wick.

Flammable Material on the Rod

The metal rod is typically coated with a substance that aids in spark production. This substance is often a blend of metals like magnesium, which ignites easily and burns at a high temperature, ensuring the ignition of the wick.

Role of the Wick and Fuel

The wick’s role is to absorb and transport the fuel, usually lighter fluid, to the point of ignition. When the sparks from the rod contact the fuel-soaked wick, a flame is produced. The quality and absorbency of the wick are crucial for consistent ignition.

Controlled Burning and Extinguishing

Once ignited, the flame can be maintained as long as there is sufficient fuel in the wick. Extinguishing the match typically involves cutting off the air supply or allowing the fuel to burn out.

Fuel Reservoir and Wick

Design of the Fuel Reservoir

The fuel reservoir in a permanent match is typically a small chamber designed to hold lighter fluid. It’s engineered to prevent leaks while ensuring easy access for refueling. The reservoir’s design is crucial for maintaining a steady supply of fuel to the wick.

Material of the Wick

The wick in a permanent match is usually made from cotton or a similar absorbent material. This material is chosen for its ability to effectively draw up and hold the fuel, ensuring it reaches the striking surface for ignition.

Fuel Absorption and Delivery

The wick’s primary function is to absorb lighter fluid from the reservoir and deliver it to the striking point. The efficiency of fuel absorption and delivery is pivotal for the match’s consistent performance.

Refueling Process

Refueling a permanent match involves adding lighter fluid to the reservoir. This process must be done carefully to avoid overfilling, which can lead to spills and safety hazards.

Maintenance of the Wick

Regular maintenance of the wick, including checking for fraying or clogging, is important for the longevity and efficiency of the permanent match. Replacing the wick when it becomes worn is also crucial.

Leakage Prevention and Safety

The design of the fuel reservoir must also focus on preventing leaks. A well-designed reservoir minimizes the risk of fuel leakage, which is essential for both safety and efficiency.

Maintenance and Care

Regular Fuel Refilling

Regular refilling of the fuel reservoir is crucial for ensuring that the permanent match is always ready for use. It’s important to use the recommended type of lighter fluid and refill it cautiously to prevent overfilling, which can cause spills and affect performance. Monitoring the fuel level and refilling it before it runs completely dry helps maintain a consistent flame.

Cleaning and Maintenance of the Striking Surface

The striking surface of a permanent match can accumulate dirt and grime over time, reducing its efficiency. Regular cleaning with a soft brush or cloth can maintain its rough texture, ensuring effective spark generation. Avoid using abrasive materials that might damage the striking surface.

Wick Care and Replacement

The wick should be periodically inspected for signs of wear or damage. A frayed or overly charred wick can hinder the flame’s consistency and may need replacing. Following the manufacturer’s instructions for wick replacement ensures the match continues to function effectively.

Storing the Permanent Match Safely

Storing the permanent match in a cool, dry place is vital for its preservation. Keeping it away from direct sunlight and high temperatures prevents damage to the fuel and other components. Additionally, ensuring that the match is properly sealed and the fuel cap is secure can prevent accidental leaks or spills.

Safety Considerations

Proper Handling During Ignition

Always strike the permanent match away from your body and face to avoid accidental burns. Ensure that the striking motion is controlled and directed away from any flammable materials to prevent unintended fires.

Ventilation When Using Indoors

If using a permanent match indoors, ensure the area is well-ventilated. The burning of lighter fluid can produce fumes, and adequate air circulation helps in dissipating these and reducing inhalation risks.

Storing Away from Children and Pets

Due to their accessibility and potential risk, permanent matches should be stored securely and out of reach of children and pets. Educating family members about the dangers and proper usage is also important.

Refueling Safely

When refilling the permanent match with lighter fluid, do so in a well-ventilated area, away from any open flames or heat sources. Use a funnel or a nozzle to prevent spills and wipe away any accidental spills immediately.

Regular Inspection for Wear and Damage

Regularly inspect the permanent match for any signs of wear, damage, or leaks. Damaged matches should not be used as they can pose a safety hazard. Replace any worn or damaged parts as necessary.

Innovations in Permanent Match Design

Waterproof and Weather-Resistant Features

One of the most significant innovations in permanent match design is the incorporation of waterproof and weather-resistant features. These advancements make permanent matches more versatile and reliable in various environmental conditions, including rain, snow, and high humidity. The waterproofing is often achieved through o-ring seals and tight-fitting components, ensuring that the fuel and striking mechanisms remain dry. This development has made permanent matches a favorite tool for outdoor enthusiasts, survivalists, and anyone needing a reliable fire source in challenging weather.

Eco-Friendly and Sustainable Materials

In response to growing environmental concerns, there has been a push towards using eco-friendly and sustainable materials in the manufacturing of permanent matches. Manufacturers are exploring alternatives to traditional metals and plastics, such as recycled materials, biodegradable components, and sustainably sourced metals. These efforts not only reduce the ecological footprint of the production process but also appeal to environmentally conscious consumers. The move towards greener materials represents a significant step in the evolution of permanent matches, aligning them with modern sustainability practices.

Advanced Striking Surfaces for Increased Efficiency

The efficiency of the striking surface in a permanent match is crucial for its overall performance. Recent innovations have focused on developing more efficient striking surfaces that require less force and produce more sparks per strike. These surfaces are often made from advanced alloys or treated with special coatings to enhance their friction and durability. This improvement not only makes the matches easier to use but also extends their lifespan, making them more cost-effective and reliable over time.

Integrated Multi-functional Tools

A growing trend in permanent match design is the integration of multi-functional tools. Modern permanent matches often include additional features like bottle openers, screwdrivers, or even small blades. These integrated tools make the permanent match a more versatile and valuable item in a user’s toolkit, particularly for camping, hiking, and survival scenarios. This innovation reflects a broader trend in product design towards multi-functionality, offering consumers more value and utility in a single, compact tool.

FAQ

Q1:How long does the fuel last in a permanent match before needing a refill?

A:The duration of the fuel in a permanent match depends on the size of the fuel reservoir and the frequency of use. Typically, with moderate use, the fuel can last for several weeks to a few months.

Q2:Can permanent matches be used in high-altitude or cold environments?

A:Yes, many modern permanent matches are designed to function effectively in high-altitude and cold environments. Innovations in fuel composition and striking mechanisms have enhanced their reliability under such conditions.

Q3:Are permanent matches safe for use by children?

A:Permanent matches are not recommended for use by children due to the inherent risks of handling fire-starting tools and the presence of flammable liquids. They should always be used under adult supervision.

Q4:Can I use any type of lighter fluid in a permanent match?

A:It’s advisable to use the type of lighter fluid recommended by the manufacturer. Using inappropriate or low-quality fuel can affect the match’s performance and may pose safety risks.

Q5:How do I dispose of an old or damaged permanent match?

A:Dispose of an old or damaged permanent match by first emptying any remaining fuel in a safe and environmentally friendly manner. The match itself should be disposed of according to local waste management regulations, particularly for items containing flammable residues.

Conclusion

In summary, permanent matches epitomize a blend of simplicity and ingenuity in fire-starting technology. Their unique design, combining a metal rod, a fuel-soaked wick, and an efficient striking mechanism, offers a reliable and sustainable alternative to traditional matches and lighters. With advancements in waterproofing, eco-friendliness, and integrated functionalities, permanent matches continue to evolve, catering to a wide range of needs from outdoor adventures to emergency preparedness. Their ease of use, coupled with effective maintenance and safety practices, makes them an indispensable tool in modern fire-starting kits.