When it comes to selecting the right type of rope for your needs, understanding the differences between paracords, tactical ropes, and braided utility ropes is crucial. Each type of rope offers unique characteristics and advantages that make it suitable for specific applications. Paracords, known for their lightweight and versatility, are often used in survival and outdoor scenarios. Tactical ropes are designed for strength and durability, making them ideal for military and law enforcement use. Braided utility ropes, on the other hand, provide excellent strength and flexibility, suitable for a wide range of general-purpose tasks. This article explores the key differences, uses, and benefits of paracords, tactical ropes, and braided utility ropes, helping you make an informed decision based on your specific needs and requirements.

Composition

The composition of paracords, tactical ropes, and braided utility ropes plays a crucial role in determining their characteristics, strengths, and suitability for various applications. Understanding the materials and construction methods used in these ropes helps in selecting the right type for specific needs. Here’s a detailed look at the composition of each type:

1. Paracords

Materials:

- Nylon: Paracords are primarily made from nylon, a synthetic polymer known for its excellent strength, flexibility, and resistance to abrasion and environmental factors. The use of nylon ensures that paracords are lightweight yet strong enough to handle various tasks.

- Inner Strands: Paracords consist of multiple inner strands, typically seven to nine, each made of twisted nylon fibers. These inner strands provide additional strength and flexibility, allowing the paracord to support substantial weight and withstand tension.

Construction:

- Kernmantle Design: Paracords are constructed using a kernmantle design, where the inner core (kern) is protected by an outer sheath (mantle). This construction method enhances the rope’s durability and ensures that the core strands are shielded from wear and environmental damage.

- Types of Paracord: Paracords are categorized into different types based on their strength and construction. Type III paracord, also known as 550 paracord, is the most common and can support up to 550 pounds. Other types include Type I, II, and IV, each with varying numbers of inner strands and load-bearing capacities.

2. Tactical Ropes

Materials:

- High-Strength Fibers: Tactical ropes are made from high-strength fibers such as Kevlar, Spectra, or Dyneema, in addition to nylon. These materials are chosen for their exceptional tensile strength, durability, and resistance to extreme conditions.

- Kevlar: Kevlar is an aramid fiber known for its high tensile strength-to-weight ratio, making it ideal for applications requiring extreme durability and resistance to heat and abrasion.

- Spectra and Dyneema: These ultra-high-molecular-weight polyethylene fibers are lightweight yet incredibly strong, providing superior performance in tactical applications.

Construction:

- Braided Construction: Tactical ropes often feature a braided construction, where multiple fibers are woven together to create a strong, flexible, and durable rope. This construction method enhances the rope’s ability to handle dynamic loads and resist abrasion.

- Protective Coatings: To further enhance durability, some tactical ropes are treated with protective coatings that improve resistance to UV rays, chemicals, and moisture. These coatings help maintain the rope’s integrity in harsh environments.

3. Braided Utility Ropes

Materials:

- Polyester: Polyester is a common material used in braided utility ropes due to its strength, UV resistance, and low stretch properties. Polyester ropes are ideal for applications where durability and minimal elongation are essential.

- Polypropylene: Polypropylene is another material used in braided utility ropes. It is lightweight, floats on water, and is resistant to chemicals, making it suitable for marine and general-purpose use.

- Nylon: Some braided utility ropes are made from nylon, offering a balance of strength, flexibility, and resistance to abrasion.

Construction:

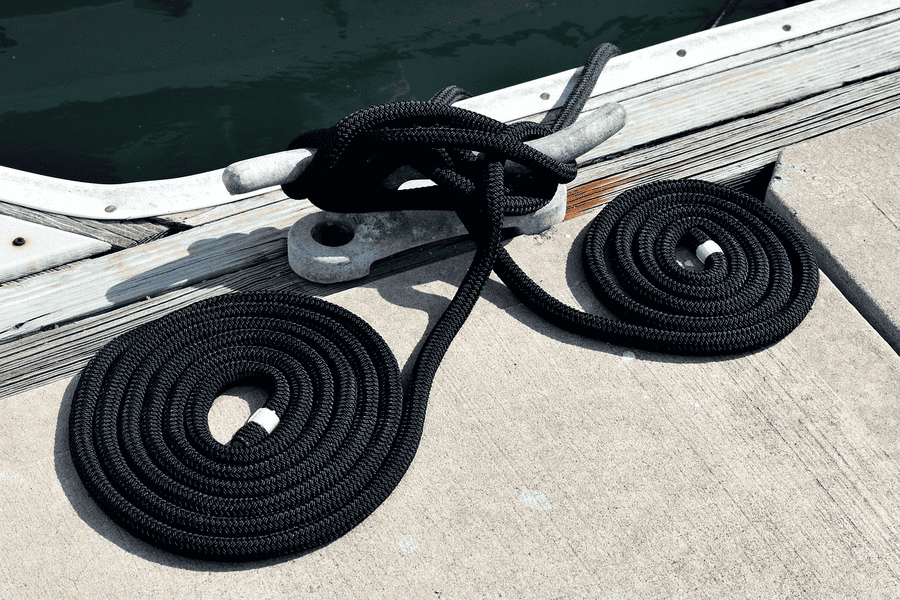

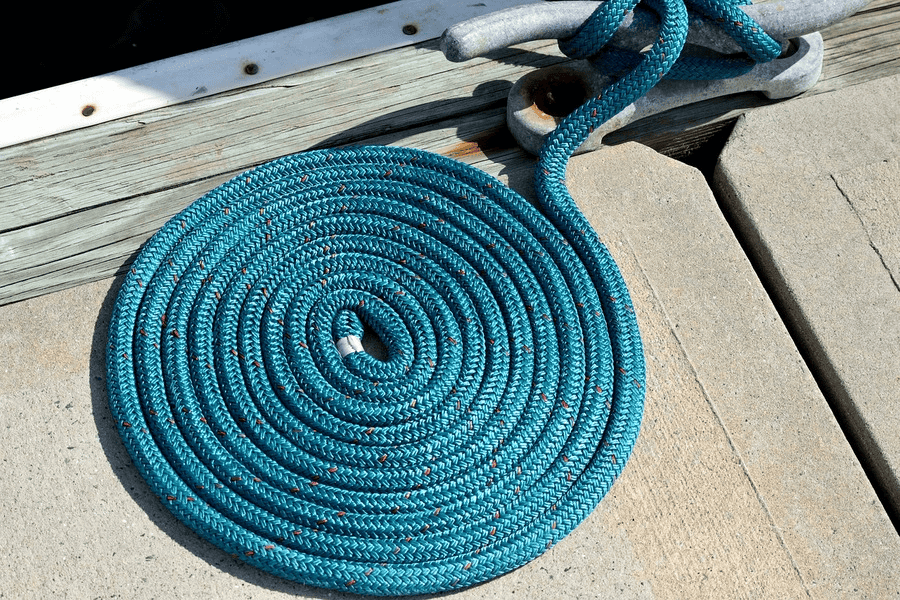

- Braided Design: Braided utility ropes are constructed using a braided design, where multiple strands are interwoven to create a flexible and strong rope. This design enhances the rope’s ability to handle various loads and provides resistance to kinking and twisting.

- Double-Braided Ropes: For added strength and durability, some utility ropes are double-braided, featuring an inner braided core and an outer braided sheath. This construction provides superior performance and reliability in demanding applications.

Comparison of Composition

Paracords vs. Tactical Ropes:

- Material Strength: While paracords are made primarily of nylon, tactical ropes utilize higher-strength fibers such as Kevlar, Spectra, or Dyneema, offering greater tensile strength and durability.

- Application Specificity: Paracords are versatile and suitable for a wide range of tasks, whereas tactical ropes are designed for specific high-stress applications, such as military and law enforcement use.

Tactical Ropes vs. Braided Utility Ropes:

- Specialized vs. General Use: Tactical ropes are specialized for extreme conditions and high-stress applications, while braided utility ropes are more general-purpose and suitable for everyday tasks and a variety of environments.

- Material Choices: Tactical ropes often use advanced materials for maximum performance, whereas braided utility ropes use materials like polyester and polypropylene for balanced performance and cost-effectiveness.

Paracords vs. Braided Utility Ropes:

- Core Design: Paracords feature a kernmantle design with an inner core of multiple strands, providing flexibility and strength. Braided utility ropes use a braided construction for overall durability and ease of handling.

- Use Cases: Paracords are often preferred for survival and outdoor gear, while braided utility ropes are chosen for general-purpose tasks, including marine, industrial, and household uses.

Break Strength

Break strength, also known as tensile strength, is a critical factor in determining the suitability of a rope for various applications. It refers to the maximum amount of force that a rope can withstand before it breaks. Understanding the break strength of paracords, tactical ropes, and braided utility ropes is essential for ensuring safety and reliability in different tasks. Here’s an in-depth look at the break strength of these types of ropes:

1. Paracords

Break Strength Characteristics:

- Type III (550 Paracord): The most common type of paracord, Type III, has a break strength of 550 pounds (approximately 250 kilograms). This makes it strong enough for many survival and outdoor applications, such as making shelters, securing gear, and crafting tools.

- Type I and II: These types of paracords have lower break strengths, typically around 100 pounds (45 kilograms) for Type I and 400 pounds (180 kilograms) for Type II. They are suitable for lighter tasks and less demanding applications.

- Type IV: Known as the strongest paracord, Type IV has a break strength of 750 pounds (340 kilograms), making it ideal for more demanding tasks where higher strength is required.

Applications and Considerations:

- Survival Situations: The high break strength of Type III and Type IV paracords makes them reliable for creating emergency shelters, making snares, and other survival tasks where dependable strength is crucial.

- Outdoor Gear: Paracords are often used in crafting durable bracelets, keychains, and lanyards that can support significant weight if needed.

2. Tactical Ropes

Break Strength Characteristics:

- High-Strength Fibers: Tactical ropes made from materials like Kevlar, Spectra, or Dyneema have exceptionally high break strengths. These materials provide tensile strengths that can range from 1,500 to over 10,000 pounds (680 to 4,540 kilograms), depending on the rope’s diameter and construction.

- Kevlar: Kevlar ropes typically have a break strength of around 8,000 pounds (3,630 kilograms) for a 1/2-inch diameter rope, making them suitable for high-stress applications such as rappelling, rescue operations, and military use.

- Spectra and Dyneema: These ultra-high-molecular-weight polyethylene ropes offer even higher break strengths, often exceeding 10,000 pounds (4,540 kilograms), making them ideal for extreme conditions and critical tasks.

Applications and Considerations:

- Military and Law Enforcement: The high break strength of tactical ropes ensures they can handle the rigorous demands of rappelling, hoisting heavy equipment, and other tactical operations.

- Rescue Operations: In rescue scenarios, the reliability and strength of tactical ropes are vital for lifting and securing individuals and equipment safely.

3. Braided Utility Ropes

Break Strength Characteristics:

- Material Variability: The break strength of braided utility ropes varies significantly based on the materials used. Polyester, polypropylene, and nylon are common materials, each offering different strengths.

- Polyester Ropes: Known for their durability and resistance to UV rays and abrasion, polyester ropes typically have break strengths ranging from 1,000 to 7,000 pounds (450 to 3,175 kilograms) depending on the diameter and braid type.

- Polypropylene Ropes: These ropes are lighter and have lower break strengths, usually between 600 to 2,500 pounds (270 to 1,135 kilograms). They are suitable for general-purpose applications where extreme strength is not required.

- Nylon Ropes: Similar to polyester, nylon braided ropes offer high break strengths, often in the range of 2,000 to 8,000 pounds (900 to 3,630 kilograms), making them suitable for heavy-duty tasks.

Applications and Considerations:

- General-Purpose Use: Braided utility ropes are used in a variety of everyday tasks, including securing loads, tying down tarps, and DIY projects. Their break strength ensures reliability for these common uses.

- Marine and Industrial Applications: The high break strength of polyester and nylon braided ropes makes them ideal for the marine and industrial applications, where durability and performance under load are critical.

Comparative Analysis

Paracords vs. Tactical Ropes:

- Strength Difference: Tactical ropes significantly outperform paracords in terms of break strength due to the advanced materials used in their construction. This makes tactical ropes more suitable for high-stress and critical applications.

- Weight Consideration: While tactical ropes offer higher strength, they are often heavier and bulkier than paracords, which are lightweight and easy to carry for everyday use.

Tactical Ropes vs. Braided Utility Ropes:

- Application Specificity: Tactical ropes are designed for specific high-stress uses and offer superior break strength. Braided utility ropes, while strong, are more versatile for general-purpose applications.

- Material Advantages: The specialized materials in tactical ropes provide extreme strength, whereas braided utility ropes use materials that balance strength with flexibility and cost-effectiveness.

Paracords vs. Braided Utility Ropes:

- Load Capacity: Braided utility ropes generally offer higher break strengths than paracords, making them better suited for heavy-duty applications.

- Versatility: Paracords are highly versatile for survival and outdoor tasks, while braided utility ropes are more commonly used in everyday and industrial applications.

Environmental Elements

When choosing between paracords, tactical ropes, and braided utility ropes, understanding how each type responds to environmental elements is crucial. Factors such as exposure to sunlight, moisture, chemicals, and extreme temperatures can significantly impact the performance and longevity of ropes. Here’s an in-depth look at how these ropes withstand various environmental elements:

1. Paracords

UV Resistance:

- Sunlight Exposure: Paracords, primarily made from nylon, offer moderate resistance to UV rays. Prolonged exposure to sunlight can degrade the fibers over time, causing them to lose strength and flexibility. For outdoor use, it’s advisable to protect paracords from direct sunlight when possible to prolong their lifespan.

Moisture and Water Absorption:

- Water Resistance: Nylon, the primary material in paracords, is hygroscopic, meaning it absorbs water. When wet, paracords can become heavier and slightly weaker. However, they dry relatively quickly and regain their strength once dry.

- Mold and Mildew: Paracords are generally resistant to mold and mildew, but constant exposure to damp conditions can eventually lead to deterioration. Ensuring they dry thoroughly after use can prevent this issue.

Chemical Resistance:

- Chemical Exposure: Nylon paracords offer good resistance to many chemicals, including oils, greases, and most cleaning solvents. However, exposure to strong acids or alkalis can damage the fibers, so it’s essential to avoid such chemicals.

Temperature Extremes:

- Cold and Heat: Nylon paracords perform well in a wide range of temperatures. They retain their flexibility in cold conditions but can become more brittle in extremely low temperatures. High temperatures, particularly above 250°F (121°C), can cause the nylon to melt or weaken.

2. Tactical Ropes

UV Resistance:

- Sunlight Exposure: Tactical ropes made from high-strength fibers like Kevlar, Spectra, and Dyneema exhibit excellent UV resistance. These materials maintain their strength and durability even with prolonged exposure to sunlight, making them suitable for outdoor and high-stress applications.

Moisture and Water Absorption:

- Water Resistance: Tactical ropes generally have low water absorption rates. For instance, Spectra and Dyneema fibers are highly hydrophobic, meaning they do not absorb water and maintain their strength when wet. Kevlar, while slightly more absorbent, still offers good performance in wet conditions.

- Mold and Mildew: These ropes are resistant to mold and mildew, making them ideal for use in humid and wet environments.

Chemical Resistance:

- Chemical Exposure: Tactical ropes are designed to resist a wide range of chemicals, including oils, solvents, and fuels. Kevlar, in particular, is known for its excellent chemical resistance, while Spectra and Dyneema also perform well in chemically aggressive environments.

Temperature Extremes:

- Cold and Heat: High-strength fibers used in tactical ropes perform well under extreme temperatures. Kevlar can withstand high temperatures up to 900°F (482°C) without significant loss of strength, while Spectra and Dyneema have lower melting points but still offer good performance in cold conditions. These properties make tactical ropes suitable for use in harsh environments, including firefighting and rescue operations.

3. Braided Utility Ropes

UV Resistance:

- Sunlight Exposure: The UV resistance of braided utility ropes depends on the material. Polyester braided ropes offer excellent UV resistance, maintaining their strength and flexibility under prolonged sunlight exposure. Polypropylene ropes, however, degrade more quickly when exposed to UV rays.

- Protective Coatings: Some braided utility ropes are treated with UV-resistant coatings to enhance their durability and longevity in outdoor applications.

Moisture and Water Absorption:

- Water Resistance: Polyester braided ropes have low water absorption rates and maintain their strength and flexibility when wet. Polypropylene ropes are also highly water-resistant and float on water, making them ideal for marine applications.

- Mold and Mildew: Both polyester and polypropylene braided ropes are resistant to mold and mildew, ensuring reliable performance in wet and humid conditions.

Chemical Resistance:

- Chemical Exposure: Polyester braided ropes offer good resistance to most chemicals, including acids and alkalis, making them suitable for industrial applications. Polypropylene ropes also resist a wide range of chemicals but are more susceptible to degradation from strong oxidizing agents.

Temperature Extremes:

- Cold and Heat: Polyester braided ropes perform well in both cold and hot conditions, maintaining their flexibility and strength. Polypropylene ropes, while performing adequately in moderate temperatures, can become brittle in extreme cold and soften in high heat. These ropes are generally not suitable for applications involving extreme temperature fluctuations.

Comparative Analysis

Paracords vs. Tactical Ropes:

- Environmental Resilience: Tactical ropes offer superior resistance to UV rays, moisture, chemicals, and extreme temperatures compared to paracords. This makes them more suitable for high-stress and outdoor applications.

- Application Flexibility: While paracords are versatile and useful in many survival and outdoor scenarios, tactical ropes provide enhanced durability and performance in demanding conditions.

Tactical Ropes vs. Braided Utility Ropes:

- Specialized Performance: Tactical ropes are designed for extreme conditions and offer exceptional resistance to environmental elements, making them ideal for military, law enforcement, and rescue operations. Braided utility ropes, while durable, are more suited for general-purpose and everyday tasks.

- Material Differences: The advanced materials used in tactical ropes provide higher performance under harsh conditions, whereas braided utility ropes balance performance with cost-effectiveness.

Paracords vs. Braided Utility Ropes:

- Water and UV Resistance: Braided utility ropes, especially those made from polyester, offer better water and UV resistance compared to paracords. This makes them more suitable for long-term outdoor use.

- Versatility: Paracords excel in versatility for survival and crafting tasks, while braided utility ropes are preferred for more robust, general-purpose applications.

Availability

When selecting the right type of rope for your needs, considering the availability of paracords, tactical ropes, and braided utility ropes is essential. Availability encompasses the ease of purchase, variety of options, and accessibility across different markets and regions. Here’s an in-depth look at the availability of these types of ropes:

1. Paracords

Market Presence:

- Widespread Availability: Paracords are widely available in numerous retail outlets, including outdoor and camping stores, hardware stores, and online retailers. Their popularity in survival, military, and recreational activities has led to a broad market presence.

- Specialized Retailers: Many specialized retailers and military surplus stores offer a wide range of paracord options, including different colors, lengths, and types (e.g., Type I, II, III, and IV).

Variety of Options:

- Colors and Patterns: Paracords are available in a vast array of colors and patterns, catering to aesthetic preferences and specific needs, such as camouflage patterns for tactical use or bright colors for visibility.

- Lengths and Packages: Paracords come in various lengths, from small bundles suitable for DIY projects to spools of several hundred feet for larger applications. This variety ensures that users can find the right amount of paracord for their specific tasks.

- Accessory Kits: Many retailers offer paracord kits that include additional accessories like buckles, carabiners, and instructional booklets for making paracord bracelets and other items.

Accessibility:

- Online Marketplaces: Major online marketplaces like Amazon, eBay, and specialized e-commerce sites make purchasing paracords easy and convenient, with options for bulk purchases and expedited shipping.

- DIY and Craft Stores: Paracords are also available in stores catering to DIY enthusiasts and crafters, reflecting their versatility and popularity in various projects.

2. Tactical Ropes

Market Presence:

- Specialized Suppliers: Tactical ropes are primarily available through specialized suppliers catering to military, law enforcement, and rescue markets. These suppliers focus on high-performance ropes designed for critical applications.

- Outdoor and Adventure Stores: Some high-end outdoor and adventure stores also stock tactical ropes, recognizing their value in extreme sports and survival training.

Variety of Options:

- High-Performance Materials: Tactical ropes are available in a range of materials, including Kevlar, Spectra, and Dyneema, each offering specific advantages in terms of strength, durability, and resistance to environmental factors.

- Specifications: These ropes come in various diameters, lengths, and tensile strengths, allowing users to choose the right rope for specific tasks, whether it’s rappelling, hoisting, or creating safety lines.

- Custom Orders: Many suppliers offer custom orders for tactical ropes, allowing buyers to specify the exact requirements for their applications, including length, diameter, and protective coatings.

Accessibility:

- Online Specialist Retailers: Tactical ropes can be purchased from specialist online retailers that cater to military and law enforcement professionals. These retailers often provide detailed product information and expert advice.

- Military and Law Enforcement Suppliers: Direct suppliers to military and law enforcement agencies provide access to tactical ropes, often offering bulk purchasing options and customized solutions.

3. Braided Utility Ropes

Market Presence:

- General Availability: Braided utility ropes are widely available in general hardware stores, marine supply stores, and home improvement centers. Their general-purpose nature makes them a staple in many retail environments.

- Industrial Suppliers: Industrial suppliers and distributors also carry a wide range of braided utility ropes, catering to construction, agriculture, and manufacturing sectors.

Variety of Options:

- Material Choices: Braided utility ropes come in various materials, including polyester, nylon, and polypropylene, each offering different performance characteristics and suitability for specific tasks.

- Construction Types: These ropes are available in single-braided, double-braided, and kern mantle constructions, providing options for different levels of strength, flexibility, and durability.

- Sizes and Lengths: A broad range of sizes (diameters) and lengths ensures that users can find the right rope for their needs, from small DIY projects to large industrial applications.

Accessibility:

- Retail Stores: Braided utility ropes are easily accessible in retail stores across various regions, making them convenient for immediate purchase for both consumers and professionals.

- Online Retailers: Numerous online retailers stock braided utility ropes, offering a wide selection of options with detailed descriptions, customer reviews, and competitive pricing.

- Bulk Purchasing: For large projects or ongoing needs, braided utility ropes are available for bulk purchase, often at discounted rates, from both online and offline suppliers.

Comparative Analysis

Paracords vs. Tactical Ropes:

- Availability: Paracords are more widely available and accessible in various retail environments, while tactical ropes are typically found through specialized suppliers and stores catering to professional markets.

- Variety: Paracords offer a broader variety of colors and patterns, appealing to a wider range of consumers, whereas tactical ropes focus on performance specifications.

Tactical Ropes vs. Braided Utility Ropes:

- Market Focus: Tactical ropes are specialized for high-stress applications and are available through specific channels, while braided utility ropes are general-purpose and more widely available in mainstream retail stores.

- Customization: Tactical ropes often offer more customization options to meet precise requirements, whereas braided utility ropes provide a wide range of standard options for everyday tasks.

Paracords vs. Braided Utility Ropes:

- Retail Presence: Both paracords and braided utility ropes are readily available, but paracords are particularly popular in survival and craft stores, while braided utility ropes dominate hardware and industrial supply stores.

- Ease of Purchase: Both types of ropes are easy to purchase through online and offline channels, ensuring that users can find the right rope for their needs quickly and conveniently.

FAQ

Q1: What are the main differences between paracords, tactical ropes, and braided utility ropes?

A: Paracords are lightweight and versatile, tactical ropes are extremely strong and durable for high-stress applications, and braided utility ropes offer general-purpose strength and flexibility for various tasks.

Q2: Can paracords be used for heavy-duty applications?

A: While paracords are strong and versatile, they are not designed for extremely heavy-duty applications. Tactical ropes are better suited for such tasks due to their higher break strength and durability.

Q3: Where can I buy high-quality tactical ropes?

A: Tactical ropes can be purchased from specialized suppliers catering to military, law enforcement, and rescue markets, as well as high-end outdoor and adventure stores and online retailers.

Q4: Are braided utility ropes suitable for outdoor use?

A: Yes, braided utility ropes, especially those made from polyester, offer good resistance to UV rays, moisture, and abrasion, making them suitable for various outdoor applications.

Q5: What is the break strength of a typical paracord?

A: The most common type, Type III paracord, has a break strength of 550 pounds (250 kilograms). Other types, such as Type I, II, and IV, have varying strengths.

Q6: How do tactical ropes perform in extreme temperatures?

A: Tactical ropes made from materials like Kevlar, Spectra, and Dyneema perform well in extreme temperatures, offering high resistance to heat and maintaining flexibility in cold conditions.

Q7: What are the common uses of braided utility ropes?

A: Braided utility ropes are used for general-purpose tasks such as securing loads, tying down tarps, marine applications, construction, and DIY projects.

Conclusion

When it comes to selecting the right type of rope for your needs, understanding the unique characteristics, strengths, and applications of paracords, tactical ropes, and braided utility ropes is crucial. Paracords offer lightweight versatility, making them ideal for survival, outdoor, and crafting tasks. Tactical ropes, with their exceptional strength and durability, are designed for high-stress applications in military, law enforcement, and rescue operations. Braided utility ropes provide excellent strength and flexibility for a wide range of general-purpose tasks, from marine to industrial and household uses.