Choosing the right striker for your Ferro rod is as important as the rod itself. But with various options available, how do you determine the best one? Let’s explore the world of ferro rod strikers.

The best striker for a ferro rod is typically made of high-carbon steel, offering the right balance of hardness and durability for effective spark generation.

Dive into the details of different strikers, their materials, and techniques to maximize efficiency and reliability in fire starting.

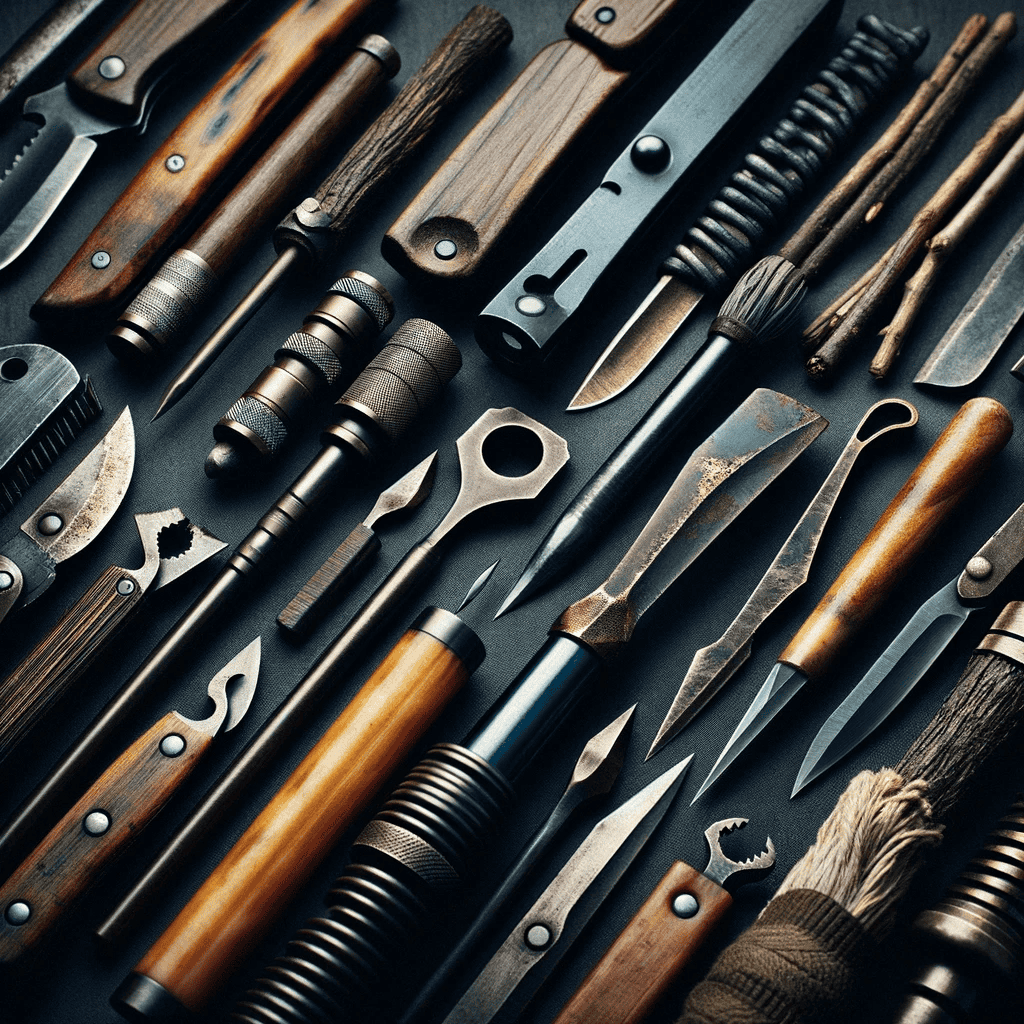

Types of Strikers

Precision and Durability

Steel strikers specifically manufactured for use with ferro rods are highly recommended for their precision and durability. They are designed to produce optimal sparks with minimal effort and wear on the ferro rod. Their ergonomic shapes often enhance grip and striking efficiency, making them ideal for both beginners and experienced users.

Improvising in the Wild

In survival situations, various makeshift items can serve as strikers. These include broken glass, another piece of metal, or even hard stones. While not as efficient as manufactured strikers or knife backs, they can be invaluable when no other options are available.

Strikers with Added Features

Some strikers come with additional features like integrated rulers, bottle openers, or even emergency whistles. These tools offer added utility and can be particularly useful in outdoor and survival kits, offering more than just fire-starting capabilities.

Personalized Striking Solutions

Custom-made strikers, tailored to individual preferences and needs, are becoming increasingly popular among ferro rod enthusiasts. These can range from hand-forged steel to creatively shaped tools using various materials, offering a unique balance of form, function, and personal style.

Material Matters

Optimal Spark Generation and Durability

High-carbon steel is often considered the best material for ferro rod strikers. Its hardness allows for efficient spark generation without causing excessive wear on the ferro rod. High-carbon steel strikers can produce a large volume of hot sparks with each strike, making them ideal for reliable fire starting. Furthermore, their durability ensures they last longer, even with frequent use. Understanding the properties of high-carbon steel can help you choose a striker that provides both efficiency and longevity.

Balancing Rust Resistance with Spark Production

While not as hard as high-carbon steel, stainless steel is another popular material for strikers. Its main advantage lies in its rust resistance, making it suitable for use in damp environments. However, stainless steel strikers may not produce sparks as effectively as their high-carbon counterparts. This section explores the trade-offs between spark efficiency and material durability, helping you decide if a stainless steel striker is right for your needs.

Exploring Beyond Traditional Options

In the quest for the perfect striker, some manufacturers and users have experimented with alternative materials. These include ceramics, certain types of stone, and even composite materials designed to strike a balance between hardness and wear resistance. While these materials may offer unique benefits, such as lighter weight or novelty, their effectiveness in spark generation varies. This comprehensive exploration delves into these innovative materials, assessing their practicality and comparing them to traditional steel options.

Striking Techniques

Fundamentals for Effective Spark Generation

The basic striking method involves holding the ferro rod firmly and striking it with the striker at an optimal angle. This section will guide readers through the fundamental technique, including how to position the rod and striker, the angle and speed of striking, and the motion required to produce the most efficient sparks.

Enhancing Efficiency and Spark Output

For those looking to refine their technique, this section delves into advanced striking methods. Topics include using different parts of the rod for varied spark patterns, adjusting striking speed for different conditions, and techniques for maximizing spark volume and temperature. This part is tailored for individuals who have mastered the basics and are seeking to enhance their fire-starting skills.

Adapting Techniques for Challenging Environments

Striking a ferro rod in adverse conditions such as rain, wind, or extreme cold requires special techniques. This section provides practical tips for adjusting your striking method to ensure reliable spark generation even in challenging weather. It covers aspects such as protecting the ferro rod from elements, positioning for wind resistance, and body mechanics to compensate for environmental factors.

Identifying and Rectifying Striking Errors

Even experienced users can fall into certain common mistakes while using a Ferro rod. This section identifies these typical errors, such as striking at an incorrect angle or applying inconsistent pressure, and offers advice on how to correct them.

Impact of Striker Shape and Size

Balancing Size for Efficiency and Portability

The size of a striker can impact its portability and efficiency. Larger strikers may provide more surface area for striking but can be cumbersome to carry. Smaller strikers, while more portable, might require more skill to use effectively. This part explores how to balance the size of the striker for your specific needs, whether for regular camping trips or emergency survival kits.

Influencing Spark Trajectory with Shape

The shape of a striker can influence the direction and concentration of sparks. Some shapes are designed to focus sparks in a specific area, which can be particularly useful when targeting a small tinder or in windy conditions. Learn how different shapes can affect spark trajectory and how to select the best shape for your fire-starting needs.

Thickness and Its Impact on Spark Production

The thickness of the striker material plays a role in spark generation. Thicker strikers might provide more durability and a larger striking surface, but they can also be heavier. Conversely, thinner strikers are lighter and more nimble but may wear out faster. This section provides insights into how to choose the right thickness based on your usage frequency and preferences.

Tailoring Strikers for Unique Requirements

Customizing the shape of a striker to suit specific uses can greatly enhance its effectiveness. This might include strikers with integrated features for multi-purpose use or shapes designed for specific types of ferro rods. Here, readers can explore how custom-shaped strikers can meet unique requirements, from survival scenarios to everyday camping use.

Custom and Improvised Strikers

The Art of Custom Striker Making

For those who enjoy personalizing their gear, creating a custom striker for a Ferro rod offers a unique opportunity. This section delves into the process of crafting a striker, including choosing the right material, shaping techniques, and adding personal touches.

Resourcefulness in Challenging Situations

In emergency situations, the ability to improvise can be lifesaving. This part focuses on how to use everyday items as makeshift strikers. It includes practical tips on identifying suitable materials and techniques for using items such as coins, broken glass, or even certain types of rocks as effective emergency strikers. This section is particularly useful for survival enthusiasts and those interested in developing their resourcefulness and adaptability in the wild.

Weighing the Pros and Cons

While improvised strikers can be invaluable in a pinch, they also come with limitations. This section provides a balanced view of the advantages and challenges of using improvised strikers. It discusses factors such as efficiency, wear and tear on the ferro rod, and safety considerations, helping readers understand when and how to use improvised strikers effectively and when it’s better to rely on a manufactured or custom striker.

Striker Maintenance and Care

Keeping Your Striker in Top Condition

Regular cleaning of your striker is essential to maintain its effectiveness. This section provides tips on how to clean different types of strikers, from steel to improvised materials. It includes advice on removing residue, preventing rust, and ensuring the striking surface is always ready for use.

Preserving Your Striker When Not in Use

Proper storage of your striker can significantly extend its lifespan. This part of the article offers guidance on storing strikers to prevent damage and corrosion. It covers factors such as humidity control, protective casing options, and ideal storage environments for different striker materials.

Optimizing Striker Lifespan Through Careful Handling

The way you handle and use your striker can affect its longevity. This section discusses techniques to minimize wear and tear, such as applying the right amount of pressure and avoiding striking methods that could damage the striker or the Ferro rod.

Routine Checks for Ensuring Striker Integrity

Regular inspection of your striker is crucial to identify any signs of wear, damage, or potential failure. This part provides a checklist for periodic maintenance, including looking for nicks or warping in steel strikers and ensuring integrated features (like whistles or bottle openers) remain functional.

FAQ

Q1:How often should I clean my ferro rod striker?

A:The frequency of cleaning depends on usage, but generally, it’s good practice to clean your striker after each use to remove any residue or buildup.

Q2:Can rust on a striker affect its performance?

A:Yes, rust can diminish the effectiveness of a striker. Regular maintenance and proper storage are key to preventing rust.

Q3:What should I do if my striker becomes damaged?

A:If your striker is damaged, assess whether it can be repaired or if it needs replacing. Some minor damages can be fixed with simple tools.

Q4:Is it possible to sharpen a blunt striker?

A:Yes, many steel strikers can be sharpened if they become blunt. This section includes tips on how to sharpen a striker safely and effectively.

Q5:How can I store my striker to ensure its longevity?

A:Store your striker in a dry, cool place. Using a protective case or sheath can also help preserve its condition.

Q6:Are there any special considerations for maintaining a custom-made striker?

A:Custom-made strikers might require specific care depending on their materials and design. This answer includes special considerations for maintaining these unique tools.

Conclusion

Selecting the right striker for your Ferro rod and maintaining it properly are crucial steps in mastering the art of fire starting. The journey to finding the best striker involves understanding the various types available, their materials, and the techniques suited to each. Proper maintenance, including regular cleaning, careful storage, and routine inspection, ensures that your striker remains effective and extends its usable life. Whether you choose a manufactured steel striker, a custom-made tool, or an improvised option, the key lies in understanding its strengths and limitations. Embrace these insights to enhance your fire-starting experience, ensuring that your ferro rod and striker are always ready to produce that vital spark when you need it most.