Source: iStock

Paracord, which is short for parachute cord, was first used in the parachutes of American paratroopers during WWII. Today, commercial paracord and mil spec paracord are valued for their high tensile strength, durability, and versatility.

If you’re a business owner, choosing the right paracord manufacturer and paracord types is crucial to keeping customers satisfied and loyal. In this article, we’ll walk you through some of the things you need to consider when buying quality paracord.

Durability and Strength of Paracord Braided Rope

Source: Pixabay

The strength of paracord plays an important role in its usefulness and reliability. Depending on its type and grade, it’s often used in heavy duty applications and situations where it needs to withstand tension or support weight. When traversing dangerous terrain or responding to emergency situations, a strong paracord ensures your safety and gives you peace of mind, knowing it won’t break unexpectedly.

Paracord strength is usually measured in pounds (lbs) or kilograms (kg). Brands and manufacturers may also use the terms “breaking strength” or “tensile strength.”

There are currently four main classifications of paracord in terms of strength:

- Type I (95 pounds, or 43 kilograms)

- Type II (425 pounds, or 192 kilograms)

- Type III (550 pounds, or 249 kilograms)

- Type IV (750 pounds, or 340 kilograms)

Paracord can also be manufactured for commercial purposes and according to military specifications. In general, military-grade paracord is designed to be stronger and more suitable for demanding tasks.

When you’re examining the strength of paracord, it’s important to take note that the strength rating manufacturers use is usually based on static force. Simply put, static force refers to a load that doesn’t move or pull on the paracord. In most cases, manufacturers will add around 20% to the minimum strength of their paracord to accommodate a margin of error.

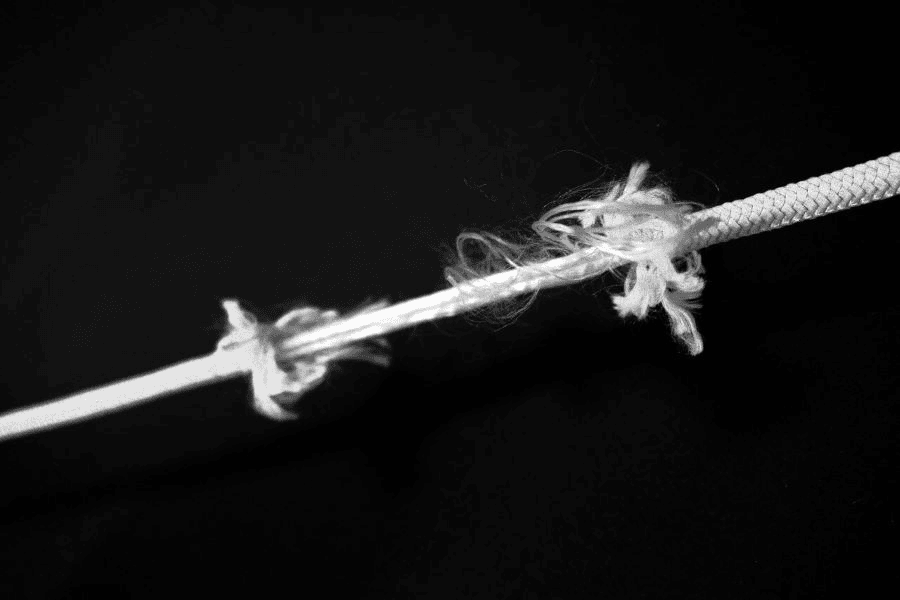

It’s not just load weight or tension that affects the strength of paracord. Here are other things that influence the strength of paracord:

- Angle: Angled paracord is weaker because of the additional stress placed on the place where it bends.

- Chemicals: Some of the chemicals that could reduce paracord strength are bleach, motor oil, or even magic markers.

- Knots: Depending on the number, knots could reduce the strength of the cord by up to 60%.

- Length: The longer the paracord, the stronger it becomes. That’s because long paracord can absorb more shock.

- Wetness and Moisture: When the paracord is wet, its fibers stretch. This makes paracord weaker (anywhere between 15% and 70%) and more susceptible to abrasion.

Core Materials Used

Source: iStock

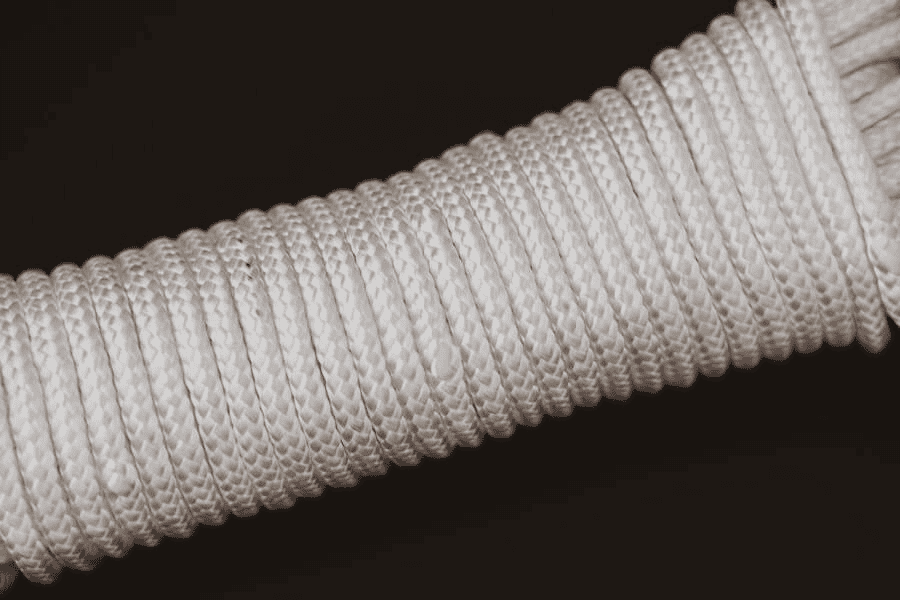

The core of parachute cords consists of anywhere from 1 to 11 strands, each made up of 2 to 3 smaller strands. The materials used for the core are important because they can affect a wide range of the paracord’s characteristics, such as its flexibility, strength, and ability to resist heat and surface damage.

Most paracord cores are made of nylon. This material provides several advantages, including high tensile strength, durability, quick drying, and flexibility (making it stretchier and more shock-resistant).

Other materials manufacturers may use for the core of paracord include:

Polyester: While nylon cord is more flexible, polyester cord is desirable because it’s more resistant to the damaging effects of UV rays and moisture. Polyester paracord also performs well, even when wet.

Dyneema: This material is also known as Ultra-High Molecular Weight Polyethylene (UHMWPE). Dyneema paracord is a suitable option for applications where extreme strength, weight savings, and resistance to damage (due to abrasion, chemicals, and UV rays) are important.

Spectra: Compared to steel, Spectra fiber is 15 times stronger. It also doesn’t absorb moisture or water, which can stretch and weaken the cord. Because of its light weight, Spectra paracord is an ideal choice for activities or tasks that require significant weight savings.

Kevlar: Kevlar paracord is stronger and more heat-resistant than standard or military-grade 550 paracord. Since it’s flame-resistant, it’s suitable for applications where open flame exposure is possible.

Technora (Aramid): Because of its extreme strength and chemical and heat resistance, Technora paracord is a valuable option for industrial applications, preventing the spread of fire, and other heavy-duty applications.

Cord Length and Thickness

Source: Pexels

The ideal length and thickness of paracord will depend on several factors, including the intended purpose and personal requirements. Here’s a general guide on the ideal length and thickness of paracord ropes based on their purpose:

General-Purpose Use: If the paracord is going to be used for a wide range of common applications (e.g., creating clotheslines and securing small gear), a paracord that’s at least 10 to 20 feet (approximately 3 to 6 meters) is a good choice. A diameter of 4 millimeters offers enough strength to handle most tasks.

Crafting Projects: The ideal length for this purpose will depend on what you plan to undertake. For instance, 10 feet (approximately 3 meters) of paracord is often enough to complete most bracelets.

Emergency and Survival Kits: For emergency preparedness, it’s recommended to carry thicker paracord (more than 4 millimeters in diameter). A length of 100 to 200 feet (or possibly longer) ensures you have enough to make emergency splints, temporary ladders, rescue lines, and improvised tools.

Outdoor Activities: Depending on the type and specific demands of your outdoor activities, carrying 50 to 100 feet (or possibly longer) of paracord can be beneficial. Choose a slightly thicker paracord, such as 5 millimeters or higher, if you expect the activity to require durability and a heavier load-bearing capacity.

Caveat: Paracord isn’t recommended for climbing, rappelling, or other high-risk activities that require you to move against gravity.

Color and Pattern

Source: iStock

The color and pattern of paracord are important for different reasons:

Camouflage and Concealment: Paracord can blend with the environment by choosing the right outer sheath color and camouflage patterns. This feature can be useful in situations where you need to maintain a low profile, such as hunting and military tactical operations.

Identification and Safety: Using different colors for different tasks helps avoid confusion and promotes safety. This is especially helpful in emergency situations, where acting fast is crucial to saving someone’s life.

Visibility: Glow-in-the-dark paracord and reflective paracord make it easier to locate and identify the cord, especially at night or in low-light conditions. These kinds of paracord are often used for pitching tents (to avoid tripping over the guy lines), marking trails, or signaling locations to planes passing by.

Personal Style and Aesthetics: The color of paracord could also be an important tool for people to express their personal style or creativity. Most manufacturers offer a wide range of colors and patterns to suit the needs of their customers.

What Paracord Manufacturer is Best?

Source: Pexels

Selling paracord can be profitable since it’s relatively inexpensive and easy to get. But first, you need a reliable manufacturer to supply you with quality paracord products that meet your requirements and budget. This step requires careful research and consideration.

Here are a few ways you can find a reliable and reputable paracord manufacturer for your needs:

Search Online

If you’re completely new to the business, Googling for the top suppliers or manufacturers of paracord products is a good starting point. You can also use B2B e-commerce marketplaces, such as Alibaba.com and DHgate, which offer various tools to filter for the kind of supplier you need.

Hire a Sourcing Agent

The role of a sourcing agent is to assist a company in finding and negotiating with suppliers or manufacturers of specific products (in this case, paracord) so the company can save money on production. This is a suitable option for people or businesses that don’t have the experience or resources to work directly with the factory.

Work With a Factory Directly

If you need large quantities of paracord, this route is one of the best ways to get the lowest prices possible. Another advantage is that you’ll have more control over the production process, so it’s easier for you to predict results.

Ultimately, choosing the best paracord manufacturer is up to you. However, if you’re looking for a good suggestion, one of the manufacturers we could suggest is Baiyuheng Outdoors.

Source: Baiyuheng Outdoors

Who are they?

Baiyuheng Outdoors is based in Jiangmen, Guangdong, China. The company has been developing and producing all kinds of outdoor and survival products, including paracord, for companies all over the world for more than a decade.

One of their popular paracord products is the Bengku 550 Paracord with 7 inner core strands. It has been tested to withstand up to 550 pounds of static weight or tension. It’s available in different lengths and colors (more than 300 options) to match your unique requirements.

There are many reasons why people keep coming back to Baiyuheng Outdoors:

- They have great customer service.

- They have a low minimum order quantity.

- They can send you a free sample of your ordered product if necessary.

- Their services also include sending free photos of the product you ordered.

- If needed, they can deliver your order directly to your doorstep. (Heads up—they usually ship right on schedule.)

Conclusion

Durability, breaking strength, core materials, length, thickness, colors, and patterns are just some of the factors that you need to carefully consider when buying paracord for your business. Make sure you partner with the right paracord manufacturer, such as Baiyuheng Outdoors, to ensure the optimal quality of your product and make a positive impact with your investment.